Reinosa Forgings & Castings is working on new innovative techniques for more sustainable steel production

ENERGY EFFICIENCY: replacement of the plant’s lighting with LEDs

8 de June de 2023Reinosa Forgings & Castings is part of the consortium of a new research project to reduce the environmental impact of steelmaking. This is the international initiative AID4GREENEST, which aims to develop innovative steel characterisation and modelling techniques based on artificial intelligence. These tools will optimise the production process to make it more efficient and sustainable. The project is part of the Horizon Europe programme and has a budget of 4.9 million euros.

Project logo

The conventional “trial and error” approach to product and process development is still prevalent in the steel industry, a practice that leads to large material waste and carbon emissions. The project consortium aims to replace this practice through six new AI-based tools. These will assist technicians in the product design and manufacturing process phases to detect failures early and reduce the production of components that need to be scrapped.

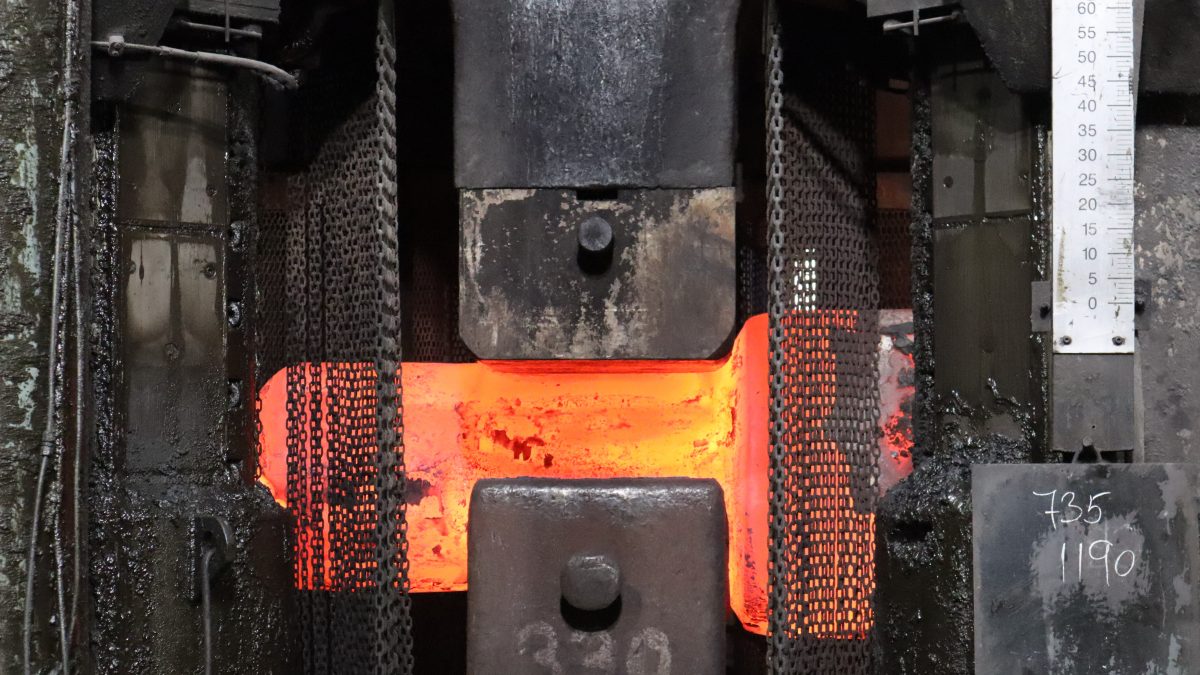

Reinosa Forgings & Castings, as part of the consortium, will carry out the design and manufacture of a prototype component for the energy sector and will analyse the production process of it through sensors. The data collected will be used, on one hand, to validate that the digital simulation models of forging and heat treatment of steel are accurate; and, on the other hand, will allow an analysis of the environmental impact of the manufacture of the part to be carried out.

The Cantabrian company will also provide representative samples of the steel at each stage of its production process. This will allow AI tools to identify errors and needs as accurately as possible thanks to learning based on historical data.

These six innovative techniques will help professionals to select the best combination of parameters and characteristics at the design stage, which will prevent the production of defective steel parts. This will allow the steel industry to reduce costs and extra time associated with the production process. The tools will also evaluate the characteristics of the steels to make them more advanced and sustainable and, therefore, offer higher quality and more durable parts to their customers.

The project is part of Reinosa Forgings & Castings’ commitment to reduce its environmental impact and promote more sustainable dynamics in the industrial sector.

The AID4GREENEST consortium is made up of ten partners from four European countries. The Spanish institute IMDEA Materials is the coordinator of the initiative, with the participation of several Belgian entities, including the Universities of Ghent and Liège and the companies OCAS NV and ePotentia; the Fraunhofer Institute for Materials Mechanics IWM and the company EurA, from Germany; and with Finnish representation on behalf of the University of Oulu. The Spanish part of the consortium is completed by the standardisation body UNE and Reinosa Forgings & Castings itself.

AID4GREENEST is funded by the European Union through the Horizon Europe Framework Program (HORIZON) for the modelling and characterisation of advanced materials under grant agreement number 101091912.